Description

An industrial conveyor system is a mechanical system used in industrial production to transport materials, components, or finished products. By utilizing automated equipment, it moves items from one process location to another, significantly improving production efficiency and reducing labor costs. These systems are widely applied in industries such as automotive manufacturing, food processing, pharmaceuticals, logistics, and electronics assembly.

Main Categories of Industrial Conveyor Systems

Types of Conveyor Equipment:

- Belt Conveyor: Uses a continuous flexible belt to transport materials, often used for light to medium loads.

- Roller Conveyor: Composed of a series of rollers, suitable for flat-bottom goods such as cartons or pallets.

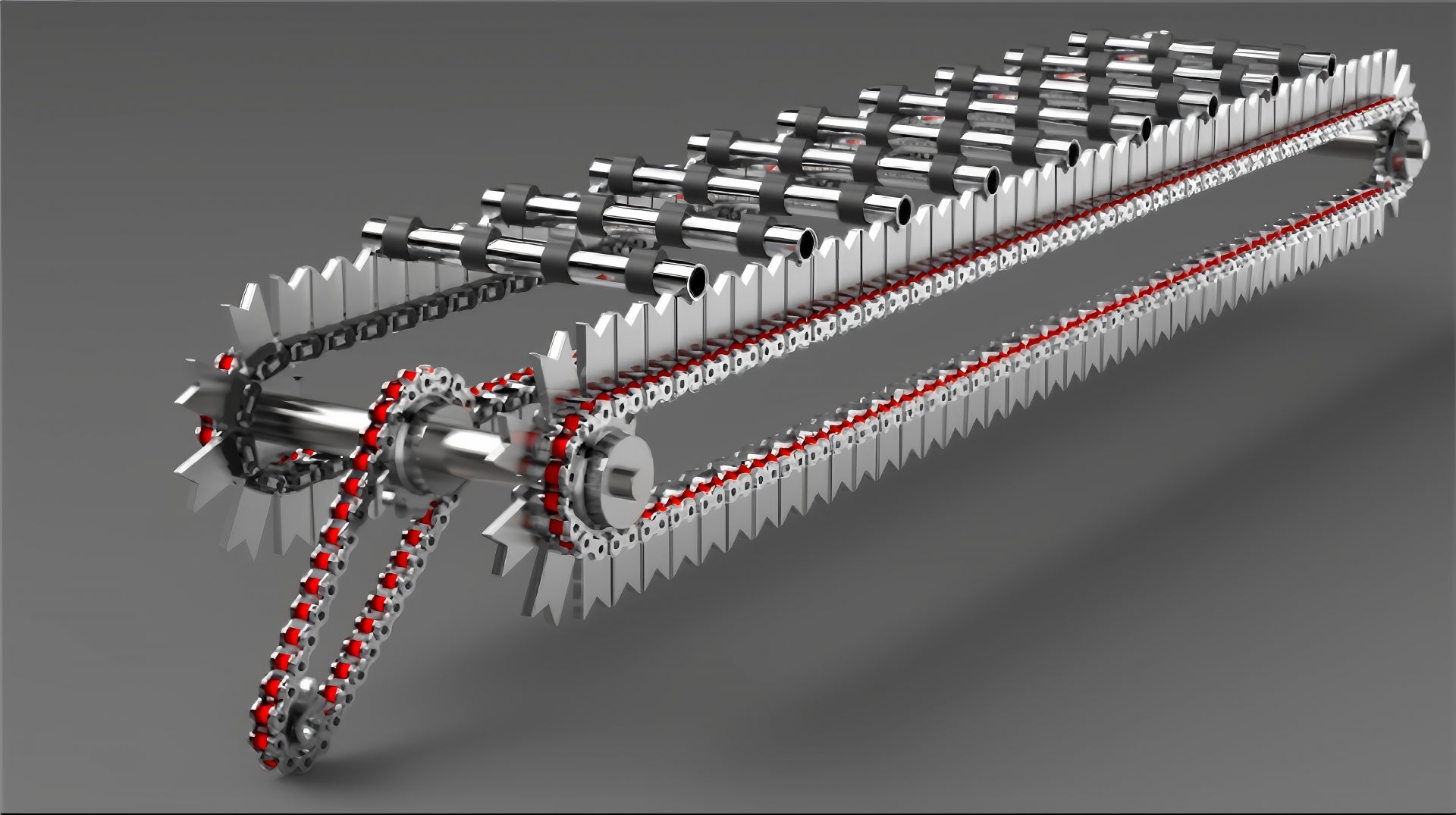

- Chain Conveyor: Uses chains to pull carriers for transporting goods, ideal for heavy materials.

- Plate Chain Conveyor: Combines chains with steel or plastic chain plates, commonly used in automotive assembly lines.

- Screw Conveyor: Transports materials using screw blades, typically for bulk materials.

- Overhead Conveyor: Materials are suspended on tracks, often used in automotive body transport and paint shops.

- Pneumatic Conveyor System: Uses airflow to transport powdered or granular materials.

By Transport Method:

- Continuous Conveyor Systems: Used for large-scale, continuous material transport (e.g., belt or plate chain conveyors).

- Intermittent Conveyor Systems: Designed for single-item or batch transport (e.g., trolley conveyors).

By Application Scenarios:

- Ground-Based Conveyor Systems: Installed on the ground for material transport or assembly lines.

- Overhead Conveyor Systems: Suspended on tracks, used for workshop material transport or automated warehousing.

Advantages of Industrial Conveyor Systems

- Efficiency Improvement: Fast transport speed reduces manual handling time and boosts production efficiency.

- Cost Reduction: Automation reduces manual operations and improves material handling accuracy.

- High Flexibility: Customizable routes (horizontal, vertical, curved) based on production requirements.

- High Reliability: Many systems come equipped with monitoring and feedback devices to ensure safe and stable operation.

- Customization: Tailored conveyor solutions are available based on industry and factory layout needs.

Application Fields of Industrial Conveyor Systems

- Automotive Industry: Used in assembly lines, engine assembly, and chassis transport.

- Logistics and Warehousing: Applied in parcel sorting, automated warehouses, and sorting systems.

- Food Processing: For raw material transport, packaging, and sorting.

- Pharmaceutical Industry: Used in drug packaging and bottle transportation.

- Electronics Manufacturing: Transfers electronic components or products in assembly workshops.

Factors to Consider When Selecting an Industrial Conveyor System

- Material Characteristics: Weight, size, shape, and material type.

- Production Requirements: Transport speed, handling capacity, and sorting functionality.

- Environmental Conditions: Operating conditions such as high temperature, low temperature, humidity, or corrosive environments.

- Layout Requirements: Length, height, and turning radius of the transport route.

- Maintenance Costs: Ease of maintenance, part durability, and replacement convenience.

Mcelty Industrial Conveyor Systems

Mcelty provides modular conveyor systems tailored to your specific transport needs. These systems ensure efficient workflows, particularly for transporting and accumulating processed workpieces and pallets.

Key Advantages of Mcelty® Conveyor Systems:

- Fully customizable for your application requirements.

- Suitable for workpieces weighing up to 4500 kg (custom designs available for higher loads).

- Accumulation and indexing systems available.

- Various roller types offered.

- Modular conveyor systems are easy to modify.

- Designed for modular assembly and transport of workpieces and pallets.

Ideal for a Wide Range of Applications:

- Handles workpieces weighing up to 500 kg.

- Automatic accumulation function independent of weight (except AL30).

- Robust, durable, and virtually maintenance-free design.

Seamless Automation:

Mcelty® conveyor systems integrate highly intelligent CNC controls, drives, a complete electrical system, and custom software. All components are perfectly coordinated. Visualization tools, camera systems, and data management solutions are further examples of Mcelty’s core expertise.