Description

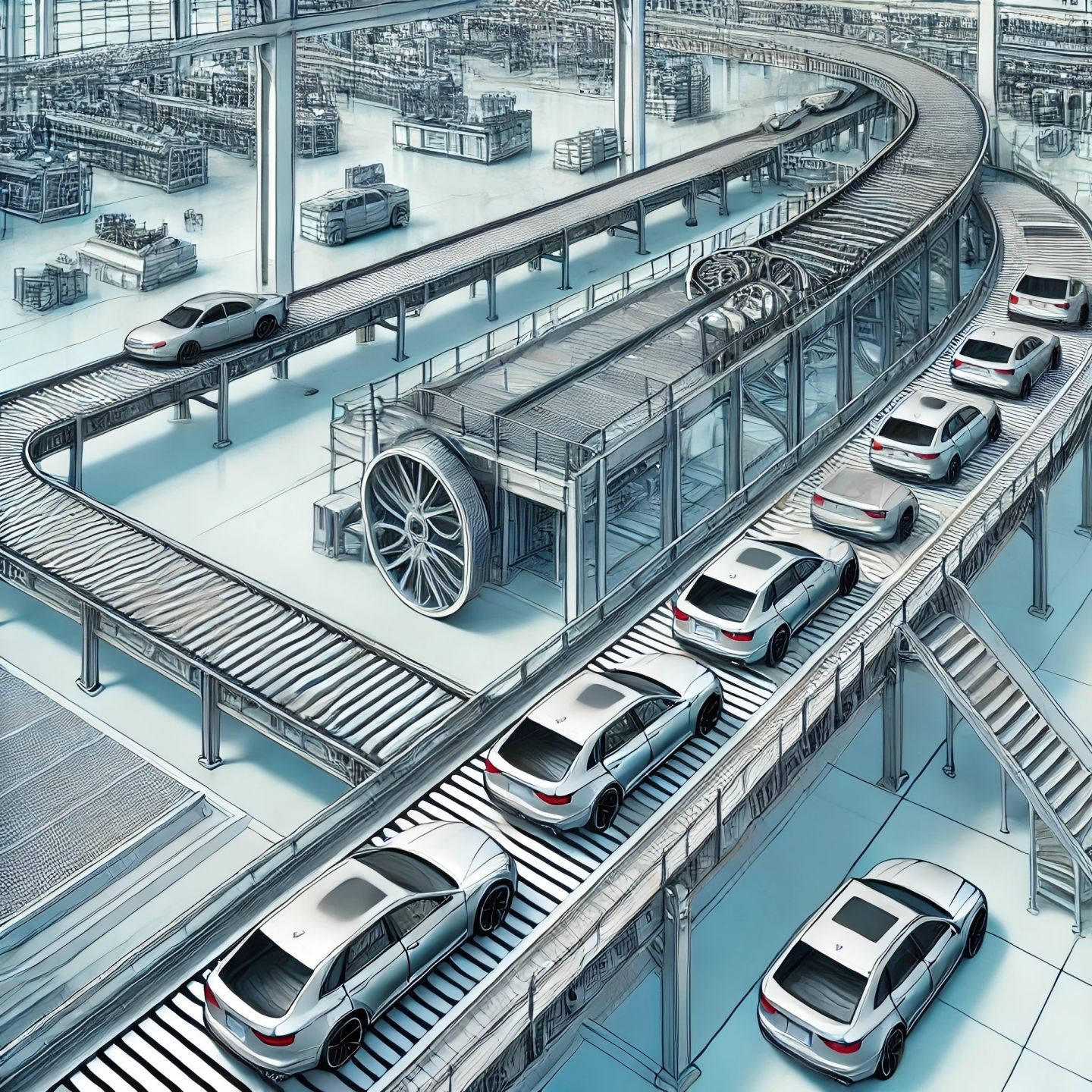

The Mcelty plate conveyor system is highly regarded across industries for its modular design and efficient performance. Below are the key features and technical parameters of the system:

The Mcelty plate conveyor system is highly regarded across industries for its modular design and efficient performance. Below are the key features and technical parameters of the system:

Key Features:

- Modular Design:

The system adopts a modular structure, allowing customization based on enterprise scale and industry needs to ensure flexibility in adapting to various production processes. - High-Efficiency Conveyance:

A single drive motor can achieve a maximum conveyor length of up to 20 meters. For distances beyond 20 meters, coupling conveyors can be used to create extended conveyor paths. - Pallet Group Configuration:

Pallets can be connected in groups to transport large and heavy workpieces. The length, width, and quantity of pallets can be customized to meet diverse production requirements. - Continuous Drive Mechanism:

The use of friction or magnetic clutches ensures continuity and stability during the conveyor process, enhancing production efficiency.

Technical Parameters:

- Conveyance Length:

A single drive motor supports up to 20 meters of conveyor distance; coupling conveyors allow for even longer transport routes. - Pallet Dimensions:

The length, width, and quantity of pallets can be tailored to suit different sizes and weights of workpieces. - Drive Mechanism:

Equipped with high-efficiency drive motors combined with friction or magnetic clutches, ensuring smooth and reliable conveyance. - Maintenance Requirements:

Designed for durability and minimal maintenance, the system reduces operating costs and improves equipment availability.

The Mcelty plate conveyor system has been successfully implemented by numerous companies worldwide, demonstrating its reliability and efficiency. For more information or detailed product specifications, visit the official Mcelty website: mcelty.com.